- HOME

- Business

- Film processing

Film processing

Processing film's surface

Our window for processing film's surface; sand-blasting, brushing, slitting and inspection is charged by KaiseiIndustries Inc. Please give them your inquiries.

Sand-blasting

Sand-blasting is a processing technology for plastic films to roughen its surface by spraying minute sand. Aptitude for printing, coating and laminating with other materials would be highly improved owing to the increase of surface area. The processed films could express a sense of luxury by vacuum deposition of metals like aluminum to the reverse. They are applied to broad spheres e.g. labels, stickers, processing films of electronic materials.

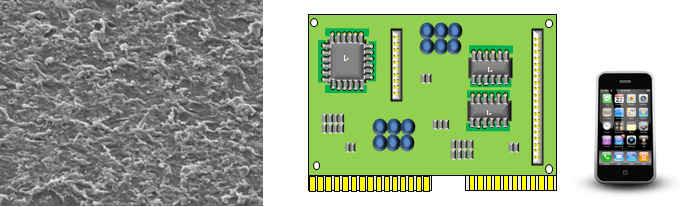

(left)An enlarged photo of a film processed sand-blasting (right)For the purpose of processing materials

Introduntion page of Sand-Blasting in KAISEI'S website

Brushing

It is the technology of decorating the surfaces, such as a PET film, with a concavo-convex like fine lines pattern with an abradant.

If vacuum deposition of the metal is carried out, the line pattern which emits metallic gloss will emerge and it will produce the sharp high-class feeling which cannot be taken out with printing.

We have broadly advanced also to durable consumption goods, such as home electronics, as transfer film uses and to labels.

(left)Brushing processed surface (right)For the purpose of durable consumption goods

Introduntion page of Brushing in KAISEI'S website

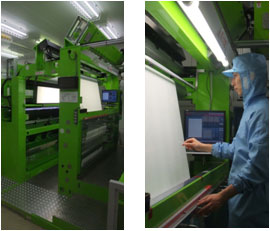

Slitting

Many customers think highly of our precise slitting technology for films of PET, TAC etc., which has various results from general indusries to optical purposes. A clean room is fully equipped with the high precision knurl processing machine after slitting, and the possibility of processing is pursued.

Slitting machine for optical films

Introduntion page of Sliting in KAISEI'S website

Inspection

State-of-the-art equipment and technology detect and remove a detailed crack, dirt, unwanted articles in a clean environment.

It has the detection level at the minimum by 0.039mm(TD) x0.025mm(MD). And

in-line film electrification measurement is also possible by 2ch electrostatic potential measuring instrument.

(left)Inspection machine (right)The scene of inspection